Products PRODUCTS

Solenoid Operated Directional Valves

Products

Solenoid operated directional valve...

Solenoid Operated Directional Valves

As follows

| Shockless type |

Wet type solenoid operated directional valves | Electrical conduit connection | Nominal size | Spool type | Coil voltage | With indicating light | Designing number for high pressure & high flow type | Manufacturing year |

| S | DF | A | 02 | Please refer catalogue pages | AC | L | 35 | 02 |

| B | 03 | DC | 35H | 03 | ||||

| C | 35C |

Wet Type (Oil Immersed) Solenoid

- Max. high pressure of 35 MPa (5,000 psi) & Max. high flow capacity of 160 l/min(42 gpm).

- Oil immersed armature provides stable, quiet operation-even under high pressure & high cycle frequency, allowing for longer valve life.

- Valve mounting accomplished without disturbing valve nameplate or electrical box.

- High tank port back pressure upto 21 MPa/3040 psi (check each spool type for max. allowable).

- Shockless type coils are available-reducing voltage spikes, providing even quieter operation and extending relay contact life.

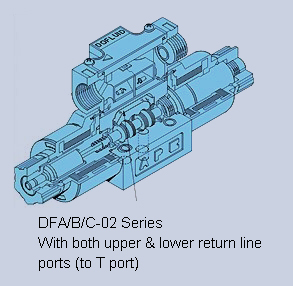

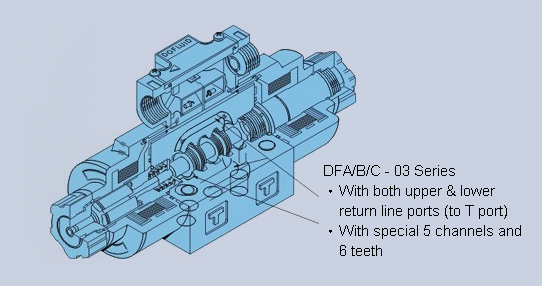

- Twin tank line design greatly reduces both pressure drop and system operating cost.

Joint Box/plug-ln Coils

- Large electrical box supplied standard, with indicator lights and terminal strip including earth ground terminal.

- Slmple design allows easy assembly and dismantling.

- Coils can be easily replaced without disturbing wiring and without risk of oil leakage.

Lead Wire Coils

- Lead wire coils available popular with the mobile industry.

- Single spade DC coil also available for one wire "spade" connection.

DIN Coils

- Manufactured to accept standard 3 pin DIN 43 650 and ISO 4400 connectors

- AC coils are rated for both 50/60 Hz service-rewiring not required if switching frequencies.

- DC coils are not polarity sensitive.

DIN Connector

Conforms to standard 3 pin DIN 43 650 and ISO 4400 standard connectors. Clear lighted connectors are supplied standard for AC coils-optional lighted connectors available for DC coils.

AC Solenoid

50-60 Hz common service solenoids do not require re-wiring when the applied frequency is changed.

Electric Shockless

AC coils can be provided with optional RAC type to include rectified coils that convert AC to DC- this reduces voltage spikes, provides even quieter operation and extends relay contact life. Coil heat generation is much less in holding applications when using rectified coils. The rectifier is supplied either in the electrical box or provided in the DIN connector.

Hydraulic Shockless

Valves can be provided with option S to slow the shifting of the spool. Oil is metered as the armature moves in the large core tube causing increased shifting times, up to 4 times normal (depending on temperature). Note :

AC valves are always supply rectified to DC valve. Shockless valves will not operate as shockless until tank line has become filled with oil-this will occur automatically after a first few cycles.

Other Notice

Pressure ratings are reduced for the tank port-check each of spool types for maximum allowable pressure (including pressure spikes). Do not supply-electric power to the AC solenoid unless the coil is mounted to the valve. Electrical power should be maintained on detented valves when in operation-the detent only maintains the valve start-up condition. When plumbing valves for 1 way or 2 way operation-flow should be limited and unused ports should be plugged (do not plug the tank port on models 2B8, 2B8L, 2D8). Do not exceed voltage specifications shown in the catalog.

Variety

There are various kinds of solenoid directional valves for your selection, which with different sizes of 1/4 & 3/8", different AC or DC solenoid, different wiring of joint box type or DIN (hirschmann) type, different spool types, with or without shockless type etc.

Fluld Types Recommended

- Petroleum based mineral oil (conform to ISO VG 32 & 46)

- Phosphate-esters based hydraulic oil.

- Water-glycol group hydraulic oil.

Fluid Temperature Range

From:+5℃ to +60℃ (41℉-140℉) recommended

Fluid Viscosity Range

15-310 cSt (80-1400 SSU) recommended

Contamination Control

Fluid contamination should be kept at/above NAS 1638-12 class and adopt filtration of 25 μm or even better filtration, otherwise, valves are easily to be damaged or shorten life.